Home / All

News

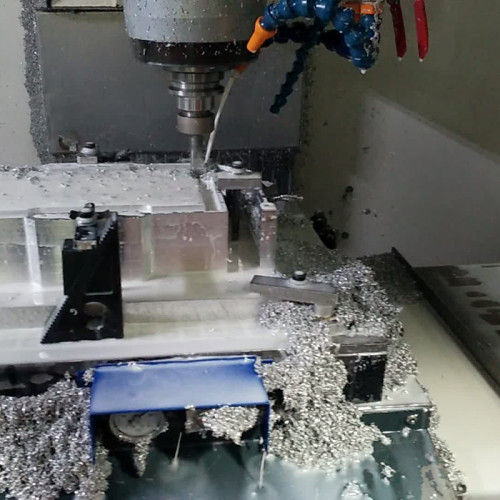

- CNC Machined Aluminum Parts Revolutionize Downlight ManufacturingAs the lighting industry continues to push the boundaries of design and functionality, CNC (Computer Numerical Control) machining has emerged as a pivotal technology in the production of aluminum parts for downlights. This cutting-edge process is transforming the way lighting components are manufactured, offering unparalleled precision and customization.Aug 28,2024

- CNC Machining Advances in Track Lighting Parts ManufacturingChinese manufacturers are setting new benchmarks in the lighting industry with their expertise in custom CNC machined brass downlight housings. Renowned for precision and quality, these manufacturers leverage cutting-edge technology and skilled craftsmanship to deliver high-performance and aesthetically pleasing lighting solutions.Jul 30,2024

- Chinese Excellence in Custom CNC Machined Brass Downlight HousingsChinese manufacturers are setting new benchmarks in the lighting industry with their expertise in custom CNC machined brass downlight housings. Renowned for precision and quality, these manufacturers leverage cutting-edge technology and skilled craftsmanship to deliver high-performance and aesthetically pleasing lighting solutions.Jun 28,2024

- Illuminate Your Outdoor Space: Landscape Lighting SolutionsDesign and Planning: This stage involves conceptualizing the landscape lighting system and its components. Designers consider factors like the type of lighting needed (ambient, accent, or task lighting), the layout of the landscape, energy efficiency requirements, and aesthetic considerations.May 24,2024

- Outdoor Lighting Parts: Anodizing VS Powder CoatingMetal lighting accessories play a crucial role in outdoor environments, where they must withstand harsh weather conditions while maintaining their functionality and aesthetic appeal.Mar 18,2024

In this guide, we delve into two primary surface treatment methods anodizing and powder coating and their significance in enhancing the durability and visual allure of outdoor lighting fixtures. - The proven properties of aluminum and aluminum alloys of CNC machining partsAluminum offers excellent machinability, durability, low weight, and low cost for a variety of parts in a variety of industries.Jul 17,2021

- Introducing Dowel PinsJeasnn custom-manufactures precision shafts and pins to your specifications, with length and diameter tolerances depending upon the size and end configuration.Jun 23,2021

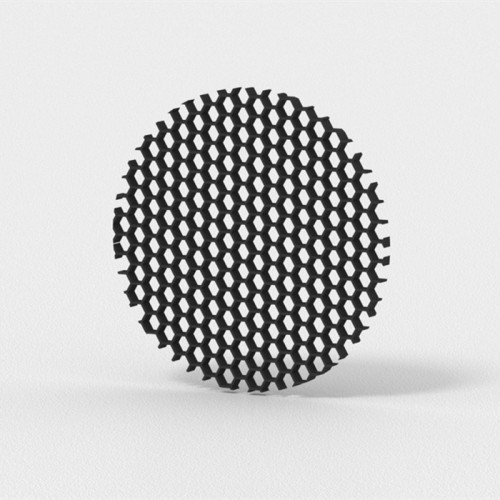

- The use of honeycomb louver in LED lightingThe most common use of the hex louver is the reduction of the glare of the light source and luminaire.Jun 18,2021

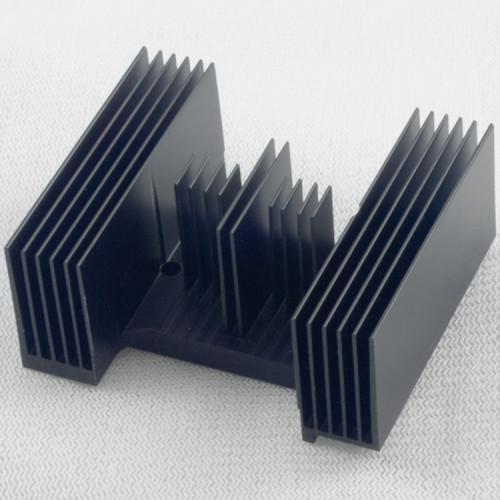

- Pros and Cons of Machined Aluminum Heat SinksMany heat sink designs require machining in order to make sure that they deal with the heat management challenge that they were designed to address.Jun 16,2021

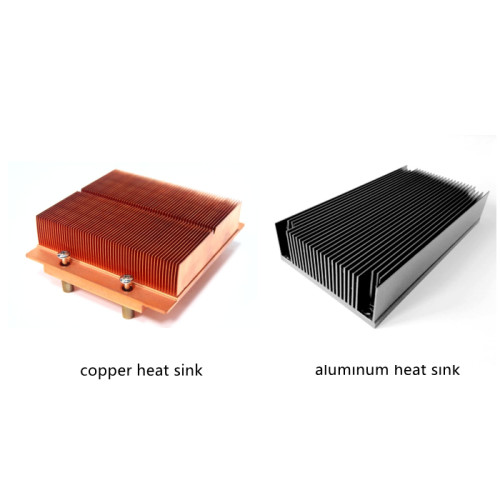

- Heat Sink Materials: Aluminum vs. CopperAluminum alloys are common heat sink material because they are cheaper than copper.Jun 13,2021

However, if you need higher levels of thermal conductivity, copper is the best option.

QUICK LINKS

Please send your message to us

- Tel

- *Title

- *Content

Contact Person

- Name:

- Lisa Lee

- Tel:

86-13528558864

86-0769-83315100

- WhatsApp:

- https://wa.me/8613528558864

- Address:

- No.48 Jinsha Second Road, Shuikou, Dalang Town, Dongguan, Guangdong, China