Heat Sink Manufacturing Technologies

Heat sink material is the basis of performance, design is the essence of the product, and ultimately whether to achieve excellent design ideas, or how to achieve the results, what kind of products customers can finally get, all depend on the use of heat sink manufacturing technology. There is a close relationship between the forming and bonding process of heat sink, and some of the technologies can be used in both processes.The most common and cost-effective technologies include extrusion, forging, casting and stamping. Other advanced technologies include CNC machining, skiving, bonding, folding, stacking, welding, and swaging. Although these manufacturing technologies are expensive, they can make heatsink with features that cannot be done by other way.

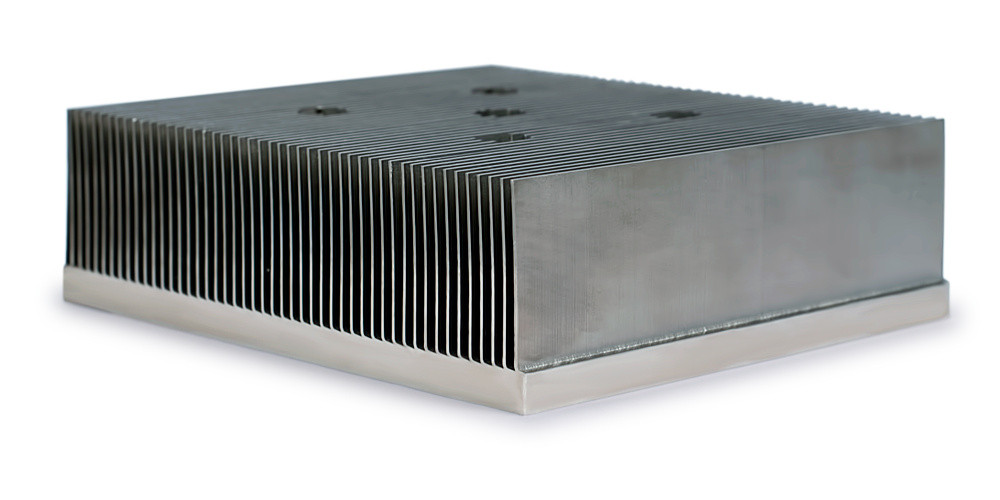

Aluminum Extrusion

The famous aluminum extrusion heat sink manufacturing is adopted by the majority of aluminum alloy heat sinks, which is the real mainstream in the market. Aluminum extrusion is the most commonly used process for processing aluminum material, which has been used in various fields. In the aspect of heat sink processing, aluminum extrusion process is mainly used to manufacture sheet fin or cylindrical fin of the initial blank.The material used in the aluminum extrusion process is usually AL6061 or AL6063.

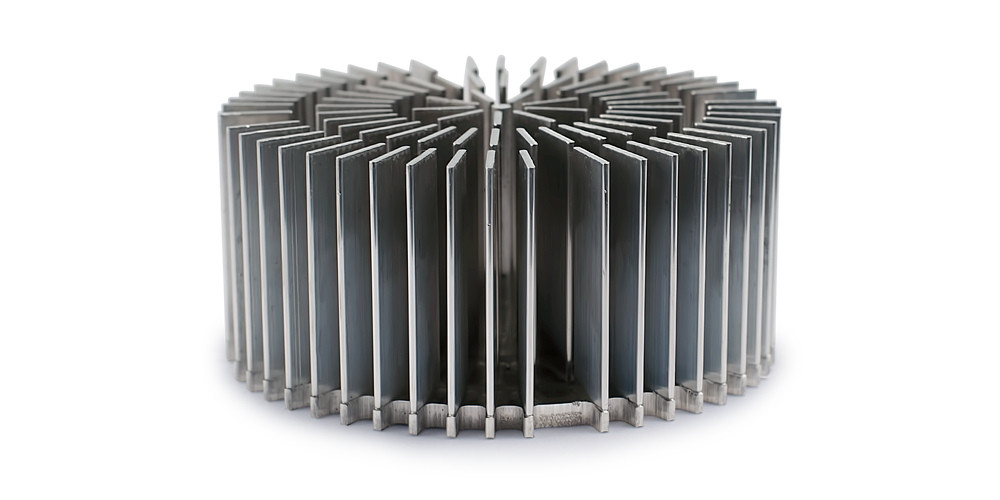

Precision Skiving

Skiving heat sink manufacturing technogy is a unique metal forming process, most widely used copper heat sink integrated forming process. "Precision Skiving" is not known from where, just from the name of the hard to imagine the actual processing technology, but with the name Skiving, it is easy to understand. Skiving, skive,means to slice. Processing method: according to the needs of a whole piece of metal profile. Using a special planer with precise control, thin slices of specified thickness are cut and then bent upward into an upright state to become heat dissipation fins.

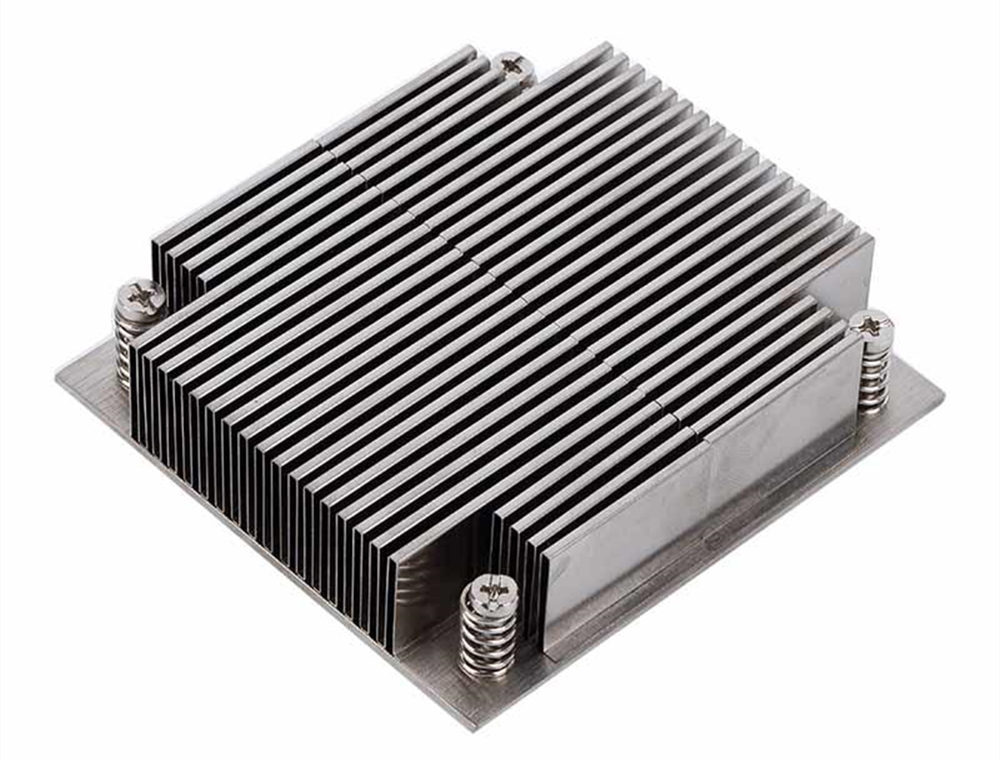

Cold forging

Cold forging is a manufacturing process in which the aluminum or copper heat sink is formed by using localized compressed forces. Fin arrays are formed by forcing raw material into a molding die by a punch. The process ensures that no air bubbles, porosity or any other impurities are trapped within the material and thus produces exceptionally high quality products.

DIE CASTING

Die casting is the manufacturing process of injecting liquid molten metal under high pressure into a high precision mold. It is often used to mass produce complex three-dimensional structures with a detailed surface texture. This is done within a single manufacturing step without post treatment. The surface of the die is quickly cooled by the mold and the slowly cooling core creates a negative pressure within the cast metal, which int urn makes it more rigid and increases its structural integrity.

FOLDED FIN

Folded fins are created by a progressive stamping method. The fins are then bonded to a base with thermally conductive epoxy, brazing, welding, or similar metallurgical bonds, to create a heat sink. An advantage of folded fin heat sinks is the ability to combine aluminum and copper to tailor the performance of the heat sink to the particular application. If the heat must be spread over a large heat sink base, copper can be used for its high conductivity, yet the heat sink fins can be produced from aluminum, due to its low weight and cost.

CNC maching

CNC maching is a versatile heat sink manufacturing technology that can produce heat sinks with the most geometric complexity, or parts that require urgent delivery, but the high cost is often a disadvantage.